Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

Choosing the right linear rail size helps things move smoothly. It also makes sure the system works well. Linear slide blocks are also called linear guide blocks. They help things move in a straight line on linear rails. In many machines, like robots or CNC machines, linear guide blocks help things move exactly the same way every time. Important things like weight, accuracy, speed, where it is used, and how it is set up all matter when picking linear rails and linear guide rails. A step-by-step plan helps you pick the best linear guide block and linear rail for your system.

Find out what the job needs before you pick linear rails. Think about weight, accuracy, speed, travel distance, and the environment.

Choose linear guide blocks and rails that can hold the heaviest loads and forces. This helps the system stay strong and last longer.

Pick rail sizes and types based on how exact and fast the system should move. Try to balance stiffness and smooth movement.

Think about where the system will work. Use sealed or stainless steel rails in dusty, wet, or clean places.

Make sure the mounting surfaces are flat and clean. Install everything the right way to keep the system precise and reliable.

To pick the right linear rail size, you need to know what the job needs. Every linear motion system has rules for how much weight it can hold, how exact it must be, how fast it should go, and where it will be used. These things help engineers choose the best linear guide block and rail. This makes sure the system works well in tough jobs like factory machines.

Engineers first figure out how much weight the system will carry. Linear slide blocks and rails hold up both still and moving forces. In factories, the load is the weight of the part that moves, any tools on it, and the force from speeding up or slowing down.

Tip: Always think about the biggest load and which way the force goes. Forces can push up, down, sideways, or at an angle. Each way changes which linear guide block you need.

Linear motion systems often get twisted or tipped by tricky forces. If the load is too heavy for the linear slide blocks, they can break or wear out fast. Picking a linear guide block that can hold the right weight keeps the system working smoothly for a long time.

Many jobs need the system to be very exact, like CNC machines, robots, and lab tools. The size and type of linear rails and guide blocks change how straight and repeatable the movement is. Bigger rails are stiffer, so they bend less. This helps keep the movement steady and exact, even with heavy loads.

Factor |

Impact of Linear Rail Size on CNC Precision |

|---|---|

Rigidity |

Bigger rails are stiffer and bend less, so the machine stays steady and cuts more exactly. |

Load Capacity |

Larger rails can hold more weight, which helps keep the machine steady when working with heavy parts. |

Tolerances |

Rails with tighter size limits move more exactly; bigger rails can help reach these limits. |

Stability |

Heavy-duty rails keep the machine from shaking or moving in ways you don't want. |

Precision |

Small rails or ball-type rails are best for tiny, careful jobs. Bigger rails are good for heavy jobs that still need to be exact. |

Maintenance |

Checking, cleaning, oiling, and tuning rails keeps them working well, no matter the size. |

Linear guide blocks with tight size limits and good bearings help the system move very exactly. For jobs that need super exact movement, like making computer chips, engineers use small, high-precision linear guide blocks. For heavy jobs, bigger rails and blocks are used to balance being exact and holding more weight.

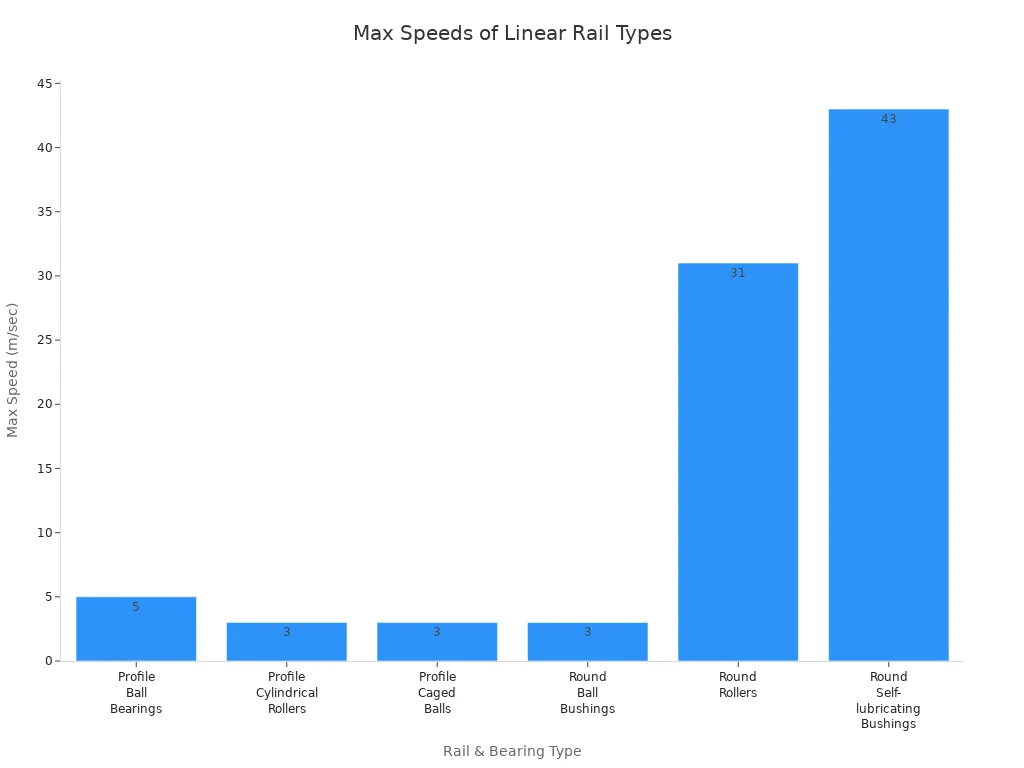

How fast and how quickly the system moves matters when picking linear rails and guide blocks. Fast machines need rails and blocks that can move quickly but still stay steady and exact. The kind of bearing inside the linear guide block changes how fast and smooth it can go.

Rail Type |

Bearing Type |

Maximum Speed (m/sec) |

Notes |

|---|---|---|---|

Profile Rail |

Ball Bearings |

Up to 5 |

Fastest for profile rails; smooth and quiet |

Profile Rail |

Cylindrical Rollers |

Up to 3 |

Can hold more weight but can't go as fast; can break if too fast |

Profile Rail |

Caged Balls |

Up to 3 |

Special cage keeps it oiled; speed is like rollers |

Round Rail |

Ball Bushings |

Up to 3 |

Speed is limited by how the balls move; about the same as rollers or caged balls |

Round Rail |

Rollers |

Up to 31 |

Chain-driven rollers go very fast and hold a lot of weight |

Round Rail |

Self-lubricating Bushings |

Up to 43 |

No need for oil, good for dirty places, fastest of all round rails |

How quickly the system speeds up or slows down also matters. In pick-and-place robots, fast moves can hit hard at the end. Engineers pick linear slide blocks that can take these hits without breaking. Soft bumpers or shock absorbers help protect the system. The total weight of everything that moves, including the linear guide block and what it carries, changes how fast the system can start and stop. For short moves, speeding up and slowing down is more important than top speed.

Note: Picking the right linear guide blocks and rails keeps the system strong and exact, even when moving fast or speeding up quickly.

Where the system works changes how well it lasts and works. In food factories, linear rails and guide blocks must not rust, must be easy to clean, and must not get dirty. Oil can catch dirt and water, so some guides use special seals or do not need oil.

Common things that affect the system are:

Dust, dirt, and water, which can wear out parts and make them less exact.

Wet air, which can make parts rust if not sealed right.

Hot or cold, which can change how oil works and make parts get bigger or smaller, hurting how exact they are.

Needing to be very clean in food or medicine jobs, where rails must handle lots of cleaning.

Engineers often pick rails with seals to keep out dust, coatings to stop rust, or made from stainless steel for tough places. Covers, bellows, and extra wipers help keep dirt away from the linear guide block and bearings. Cleaning and oiling the system often helps it last longer.

Tip: Always pick linear guide blocks and rails that can handle the place they will be used. This keeps the system working well and cuts down on repairs in factories.

Picking the right linear slide blocks and rails for the job is very important for a system that works well. If parts do not fit together right, they rub too much, wear out early, and do not move as exactly. Mounting the parts right and picking the best linear guide blocks and rails keeps the system moving smoothly and exactly for a long time.

In summary, engineers should:

Find out how much weight, how exact, how fast, and what kind of place the system needs.

Pick linear guide blocks and rails that meet or beat these needs.

Think about how speeding up, how far it moves, and the place affect the system.

Keep the system clean and oiled, and use covers to help it last.

By doing these things, engineers can build systems that move smoothly and exactly in many jobs, from factories to labs. Picking the right linear guide block and rail helps the system move well, stay exact, and last a long time in all kinds of linear motion systems.

Engineers must understand the forces acting on linear motion systems to choose the right rail size. In linear motion, two main types of loads affect the system: static loads and dynamic loads. Static loads act on the linear rail when the system is not moving. These include the weight of the part and any tools attached. Dynamic loads happen when the system moves. Acceleration and deceleration create extra forces that the linear motion system must handle.

When calculating loads for linear motion, engineers look at forces in different directions. The Z direction (up and down) has tension and pressure. The Y direction (sideways) has side loads. Engineers also consider moments, which are twisting forces. These include roll (Mx), pitch (My), and yaw (Mz). Each force and moment affects how the linear motion system works.

Forces in Z direction: tension and pressure (Fz)

Forces in Y direction: side loads (Fy)

Moments: roll (Mx), pitch (My), yaw (Mz)

Linear motion systems have ratings for how much load they can handle. The dynamic load capacity (C) shows how much load the system can take while moving for a long time. The static load rating (C0) shows how much load causes a small, permanent change in the rail or block. Engineers use a combined equivalent bearing load formula to add up all the forces and moments. This helps them see if the linear motion system can handle the job.

Tip: Preload forces make the linear motion system stiffer and more precise. If the applied load is much higher than the preload, engineers can ignore the preload in their calculations.

Moments are twisting forces that act on linear motion systems. In automation, moments can come from loads hanging off the side or from fast starts and stops. Engineers calculate moments in three ways: pitching, yawing, and rolling. The direction of the moment depends on how the linear motion system is set up and where the load sits.

Pitching moment: caused by loads far from the rail, making the system tip forward or backward.

Yawing moment: caused by side loads, making the system twist left or right.

Rolling moment: caused by uneven loads, making the system roll along its length.

In multi-axis linear motion systems, engineers start with the outermost axis and move inward. They add up the moments from each axis and check if each one stays below the system's limit. This keeps the linear motion system safe and steady.

Safety factors help protect the linear motion system from unexpected loads. Engineers divide the static load rating (C0) by the combined static load to get the safety factor. A higher safety factor means the system can handle surprises, like sudden stops or extra weight.

Note: Always check that the linear motion system's moments and loads stay within safe limits. This keeps the system working well and prevents damage.

Engineers pick how long linear slides should be. They think about how much support and accuracy the system needs. Longer linear slides have more rollers inside the linear guide block. More rollers help the system move straighter. They also make the system stronger. When there are more rollers, the load spreads out. This makes the system stiff and keeps it moving exactly. It works well even with heavy loads or fast speeds.

Longer linear slides help with small mistakes in the mounting surface. The extra length helps the block move over bumps or small errors. This makes the system run better and stay steady. Many automation systems use longer rails and guide blocks. This gives them high strength and good travel accuracy. The length engineers choose depends on the job, the weight, and how exact the movement needs to be.

Note: Longer linear slides with more rollers give better support. They can hold more weight and help the system move more exactly in tough jobs.

Travel means how far the linear guide block moves on the rails. Engineers call this distance the stroke. They pick the stroke by looking at how much movement the job needs. For example, in packaging, the block must move a set distance for each task. The rail length sets the longest travel. If the job needs more, engineers can join rails together.

Engineers also think about overrun. Overrun is extra space at each end of the rail. This space lets the block slow down and stop safely. Without enough overrun, the block could hit the end and break the system. Engineers check how long the system needs to last. They guess how far the block will move before it needs to be replaced. Sometimes, this is thousands of kilometers.

Stroke is the total distance the block moves.

Required life is how far the block must go before replacement.

Rails can be joined for longer travel.

Overrun space keeps the system safe during fast moves.

Load, accuracy, and where the system works change travel and rail choices.

Engineers mix different slides, guide blocks, and rails to make custom systems. They match the length, travel, and support to each job. This helps them build strong and reliable systems for many uses, like packaging and robots.

The mounting surface is very important for how well the system works. Engineers must make the surface smooth and flat. This helps the linear slide blocks and rails move without problems. If the surface is not flat, the carriage can bend. This can make the system slip or move the wrong way.

The surface must be very flat, with a flatness of 5 microns. This stops the carriage from bending and keeps movement smooth.

Rails should sit on a special flat area called a reference plane. This keeps the rails straight and helps the system move right.

Before putting on the rails, engineers clean the surface to get rid of dirt. Sometimes, they use a stone to make the surface even better.

When they put on the rails, they tighten the screws in order. They also push the rail onto the reference plane to keep it in place.

Rails often have special flat sides to help put them on straight. These sides help with careful setup and checking.

If the mounting surface is clean, flat, and lined up, the system works better. It will be more exact, stronger, and last longer.

Space limits often change how engineers design the system. In small machines, parts must fit into tight spaces. Engineers use different ways to solve these problems:

Track actuators keep the moving part inside the main body. This saves space and makes it easier to put in.

Low-profile linear slides are very short, sometimes only 6 mm tall. These fit in small places but still let things move smoothly.

Miniature guide rail assemblies are small but can hold a lot of weight. Engineers use them in medical, lab, and factory machines where space is tight.

Special holes and finishes help parts fit into odd spaces.

Sometimes, engineers use just one slide block or put two blocks close together. This can make the load uneven, so they use special math to keep things safe.

Manufacturers make slim and mini linear guide blocks for small spaces. These blocks help things move smoothly even if the load changes. Engineers can pick one rail or more, and change the preload to fit the job. By choosing the right parts, engineers build systems that fit in small spaces and still work well.

Engineers look at datasheets before picking linear motion systems. These datasheets have important facts about linear slides, rails, and blocks. The specs help people pick the right parts for their job. Some key things are size, how much weight it can hold, what it is made of, and special features. The table below shows some specs you might see in a datasheet:

Specification |

Details |

|---|---|

Space Envelope Width |

32.5 mm – 33.5 mm |

Height |

80 mm |

Rail Length |

200–3000 mm |

Maximum Load Capacity |

70–280 kg/pair |

Bearing Type |

Double row angular contact, steel, or Delrin bearings |

Material |

Aluminum or aluminium |

Hardness |

Inserts hardened to 60 HRC |

Surface Treatment |

Chrome plated inserts |

Dust Protection |

Yes |

Lubrication System |

Standard on carriers |

Preload Adjustability |

Adjustable via eccentric bearings |

Load Capacities (N) |

Fy 520N, Fz 1200N |

Precision & Robustness |

High precision, self-aligning |

Companies like Weikente give out brochures and guides. These papers show how to clean, oil, and put in linear slides the right way. They also tell you how to set preload and pick the best system for each job.

Tip: Always check datasheets and guides to make sure the system fits your needs for weight, accuracy, and where it will be used.

Many companies have online tools to help pick linear motion systems. These tools help engineers find the best system for their job. The tools ask about weight, speed, how often it moves, space, and which way it sits. They also help figure out forces like sideways, up and down, and twisting.

Selection tools tell you the best bearing type and size for your system.

They suggest bigger models if there are twisting or tipping forces.

The tools remind you to think about how you will mount it and the place it will be used.

If the load is heavy or the system will not last long, the tools may tell you to use more slides or a different model.

Safety tips pop up for upside-down setups.

These tools make it easy to compare different slides and blocks. They help you pick the best one for your needs.

Real-life examples show how engineers use linear motion systems in many jobs. The table below lists some jobs and why certain slides and rails are picked:

Application Example |

Preferred Rail Geometry |

Drive Type |

Bearing Type |

Key Reason for Selection |

|---|---|---|---|---|

Laser Cutting Stage |

Square Rail |

Ball Screw |

Ball Bearings |

Needs strong push and flatness for accuracy |

Vision Inspection |

Air Stage |

Linear Motor |

Air Bearings |

Needs to move the same way every time and be smooth |

Palletizing |

Square or Round Rail |

Belt Drive |

Ball Bearings |

Needs to go far and fast |

Vertical Pressing |

Cross-Roller Rail |

Ball Screw |

Cross-Roller |

Needs to hold a lot of weight up and be stiff |

Engineers often use slides from brands like Weikente for these jobs. They pick systems that match the weight, speed, and accuracy needed. Looking at these examples helps people see how to check their own choices.

Picking the right linear rail size means following some easy steps. First, think about what the system needs to do. This includes how much weight it will carry, how exact it must be, how fast it should move, how far it travels, and where it will work. Next, look at how many directions or axes the system will move in, and how far it needs to go each way. Then, check how much weight the rail can hold, how stiff it is, and how well it handles twisting or tipping. After that, pick the kind of rail and how you will attach it before you finish your design. Make sure the rail has good oiling, seals, and covers to keep it working well. Choose a drive part that fits what the system needs to do. Last, use tools from the maker to double-check the size and how long the rail will last.

If the project is tricky, engineers should ask the company or an expert for help. These people can help match the system to the right rail, give advice, and stop mistakes that could cost a lot.

A linear motion system moves objects in a straight line. Engineers use these systems in machines like robots and CNC tools. Linear slide blocks and rails guide the motion. The system helps parts move smoothly and accurately.

Engineers look at the load, speed, and environment. They check how much weight the linear slide blocks must carry. They also consider the type of linear motion needed. The right block keeps the motion smooth and safe.

The size affects how much weight the block can hold. Bigger blocks support heavier loads and keep the motion steady. Small blocks work for light loads and precise motion. The right size helps the system last longer.

A linear ball bearing slide block uses balls to reduce friction during motion. This makes movement smoother. A linear bearing slide block may use rollers or bushings. Each type changes how the motion feels and how much weight it can hold.

Yes, engineers pick linear slide blocks with seals and special coatings. These features protect the block during motion. Stainless steel blocks resist rust. Covers keep dirt away. The right choice keeps linear motion reliable in tough environments.