Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

You may ask if linear rails are better than linear rods. The answer depends on what you need for accuracy, weight, and automation. Linear rails can hold more weight and are stronger. They also help things move more exactly. Linear slide blocks and linear guide block systems are important in automation. They help things move smoothly and work well. When picking linear motion systems, think about how flat the surface is, how much it costs, and what your guides or slides need.

Linear rails with slide blocks are more accurate. They can hold heavier things. They move more smoothly than linear rods.

Linear rods are easier to use. They cost less money. You can install them quickly. They work well for light or medium jobs. They are good if you do not need perfect accuracy.

Pick linear rails for big machines. Use them for robots and CNC machines. They are best when you need things to be exact and strong.

Clean and oil slide blocks often. This helps them last longer. It is important in dirty or rough places.

Think about your project’s weight and how exact it needs to be. Also think about your money and where you will use it. This helps you choose the best system for smooth and steady movement.

Linear slide blocks are important in many linear motion systems. People also call them carriages or sliders. They move along linear guide rails. These blocks carry loads and help things move with high precision. Inside, ball bearings or rollers help reduce friction. This makes the movement smooth and controlled. The block’s body keeps it stable and strong as it moves on the rail. Seals keep dust and dirt out of the inside parts. Lubrication channels help everything work well and last longer.

Linear slide blocks work with linear guide rails, drive units, and control systems. This teamwork helps machines move accurately and the same way every time. Linear slide blocks are used in jobs that need high precision. You can find them in CNC machines, robotics, and laboratory automation. The design uses ball bearings that touch the rail at a 45° angle. This spreads the load out evenly. It also makes the block more stable and accurate. That is why linear slide blocks are great for tough jobs.

Tip: If you want smooth, exact, and steady movement in your project, linear slide blocks are a good choice.

Linear rods are also called linear bearing shafts. They are simple round bars made from strong materials like CF53 steel or stainless steel. You will see these rods in many linear motion slides and automation systems. Makers use special hardening and grinding to make the surface smooth. This helps lower friction and keeps the rod working well.

You can get linear rods in many sizes, from 5mm to 60mm wide. The size you pick depends on how much weight you need to carry and how much space you have. Linear rods work with linear bearings or bushings that slide along the round rod. This setup lets things move smoothly. But it does not give as much strength or load support as linear rails with slide blocks. Linear rods are cheaper, easy to put in, and do not need much care. They do not wear out fast and do not rust easily. This makes them good for many factory jobs.

Both linear slide blocks and linear rods are used in automation systems. But they are used for different reasons. Here are some common types of linear slides and what they are used for:

Linear Slide Blocks and Linear Guide Block Applications:

Manufacturing equipment and machine tools

CNC machines and 3D printers

Robotics, including pick-and-place robots

Laboratory automation and diagnostic devices

Semiconductor manufacturing

Conveyor systems and material handling equipment

Factory automation systems that need high precision and can carry heavy loads

Linear Rods and Linear Bearing Applications:

3D printers and light machinery

Hobby projects and DIY automation

Industrial enclosures and simple material handling

Projects that need to save money

Systems where medium precision and load are enough

You can look at this table to compare linear slide blocks and linear rods:

Feature/Aspect | Linear Rods (Linear Shafts) | Linear Slide Blocks (Linear Rails) |

|---|---|---|

Structure | Metal shafts, ground smooth and straight | Rails with ball bearings touching at certain angles (like 45°) |

Shape | Round bars | Flat, long, and rectangle-shaped |

Surface | Smooth round surface | Flat surface that is very smooth or hardened |

Bearing Contact | Bearings or bushings slide along the rod | Ball bearings touch the rail at a 45° angle |

Load Capacity | Medium | High |

Rigidity | Not as strong | Very strong and stable |

Precision | Good for medium precision jobs | Very precise, good for CNC and robotics |

Friction and Noise | More friction and noise | Less friction and noise |

Installation | Easier and costs less | Harder to install, costs more |

Maintenance | Needs little care | Easy to care for, parts can be changed |

Application Examples | 3D printers, light machines, hobby projects | CNC machines, robotic automation, precise factory jobs |

Cost | Cheaper | Costs more |

Self-Alignment | Cannot align itself | Can align itself to fix mounting mistakes |

Contact Under Load | Bearings slide on rods | Ball bearings keep touching under pressure for smooth movement |

Note: Pick linear slide blocks and linear guide block systems if you need high accuracy, stability, and to carry heavy loads. Linear rods are better for simple, lighter, and cheaper projects.

When you choose a linear motion system, think about what you need. If your project needs high precision, smooth movement, and strong support, linear slide blocks and linear guide rails are best. If you want something simple and cheap for medium loads, linear rods with linear bearings are a good choice. Both types are useful in automation. Knowing the differences helps you pick the right one.

A linear guide block is known for being very precise and strong. It uses ball bearings that touch the rail at a 45° angle. This helps spread out the weight and keeps things moving smoothly. A linear guide block can hold heavy loads without losing accuracy. Some systems use special ball patterns, like O-shapes, to make them even stronger. This makes them much more stable than linear rods.

Here is a table that shows how linear guide blocks and linear rods are different:

Feature | Linear Guide Blocks (Linear Rails) | Linear Rods |

|---|---|---|

Design | Ball bearings touch rails at a 45° angle to spread weight | Ball bearings touch the shaft directly |

Load Capacity | Can hold heavy loads because of special ball patterns | Can hold medium loads |

Rigidity & Stability | Very strong and stable, good for heavy things | Not as strong or stable with heavy things |

Precision | Stays very precise even with heavy loads | Pretty precise but not as good as rails |

Friction & Wear | Less friction and wear, so it lasts longer | More friction and wears out faster |

Resistance to Deformation | Hard to bend or change shape, works well for a long time | Easier to bend or change shape |

Speed Capability | Can move fast, up to 3 m/s, good for quick and exact jobs | Usually moves slower |

Cost & Maintenance | More parts, can cost more and need more care | Cheaper and easier to take care of |

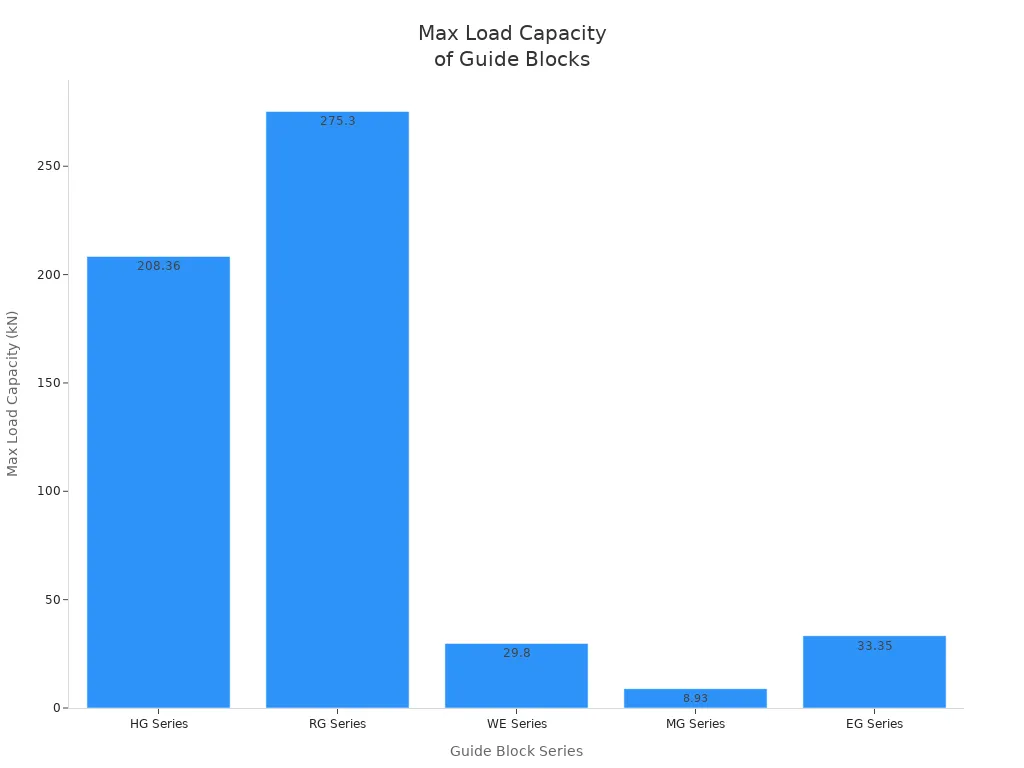

A linear guide block works better for jobs that need high precision and can carry heavy things. Some types, like HG and RG, can hold loads from 11 kN to over 275 kN. The chart below shows how much weight different linear guide block types can hold:

A linear guide block can last for many years, even if you use it a lot. Most last about 5 to 10 years if you use them the right way. How long they last depends on the weight, speed, and where you use them. If you use them in a clean place, they last longer. Some systems have special seals and oil channels to keep dirt out. This helps the linear guide block stay strong and not wear out.

In tough places, a linear guide block works better than a linear rod. The seals and dust covers protect the moving parts. You can use them in dusty or dirty places. They keep working well and do not break down fast. Linear rods have simple seals and need more care to stop dirt from causing problems.

Tip: For hard jobs or dirty places, pick a linear guide block with good seals and a strong build. This helps your system last longer and work better.

You need to take care of your linear guide block to keep it working well. Here are some easy steps:

Clean the linear guide block often to get rid of dust.

Add oil or grease at the right spots to stop friction.

Check for damage, like scratches or loose parts.

Make sure it moves straight and does not get stuck.

Keep it safe from water, dust, and very hot or cold air.

Use covers or wipers if your area is dirty.

Change old parts with good ones from trusted brands.

A linear guide block usually needs less care than a linear rod, especially in tough places. The seals and oil systems help keep it clean and working well. If you take care of it often, your linear guide block will last longer and work better.

When you put linear slides in your project, think about time and work. Linear rails need careful mounting. You must use many mounting holes. They also need strong support under them. This can take more time and feel hard to do. But linear rails help you line things up better. This makes your setup more exact in the end. Linear rods are much easier to put in place. You only need to fix both ends. This simple way saves time and lowers mistakes. Linear rods also cost less at first. They are good for projects with small budgets. Over time, linear rails might save money. They last longer and need less care, especially in busy factories.

You will see big differences in how linear rails and linear rods work. Linear rails use rolling friction. Ball bearings roll along the rail. This gives you smooth movement, high speed, and great accuracy. Most linear rails can go up to 3 meters per second. Some special rails can go even faster. Linear rods use sliding friction. They work best for light or medium loads. They do not move as fast or as smooth. If you need high precision, like in CNC machines or 3D printers, linear rails and linear guide rails are better. They can carry heavy loads and keep machines running well for a long time. Linear rods are good for simple jobs that do not need much accuracy.

To pick the best linear slides, look at a few things:

Think about how much weight your system will carry. Heavy loads need linear rails.

Check how much precision you need. Jobs like robotics or making things need linear rails.

Look at your budget. Linear rods cost less at first but may wear out sooner.

Think about the place you will use them. Dust, heat, or water may need special seals or materials.

Plan for care. Linear rails need less care if you put them in right.

Measure your space. Some systems need more room to fit.

Here is a quick chart to help you choose:

Feature | Linear Rails | Linear Rods | Linear Slides (General) |

|---|---|---|---|

Installation | Harder, needs care | Easy, fast | Changes by type |

Cost | Costs more at first | Costs less at first | Changes by type |

Precision | Very high | Medium | Depends on type |

Load Capacity | High | Medium | Changes by type |

Maintenance | Low (if set up well) | Low to medium | Changes by type |

Speed | High | Medium | Depends on design |

Best Use | Factories, robotics | Light jobs | Many uses |

Tip: Always pick linear slides that fit your project. If you want smooth, exact, and long-lasting movement in factories, choose linear rails or linear guide rails. For simple and cheap projects, linear rods may be enough.

You now understand how linear rails, linear rods, and slide blocks are different. Linear rails help you get the most accurate movement and can hold heavy things. They work best for tough automation jobs. For jobs that need exact movement, systems like Bosch Rexroth’s TCRS save money and last a long time. Always look at how much weight you need to move, how fast things should go, and where you will use them before picking. Make sure you install everything the right way and take care of it so your system works well.

A linear slide block helps you move objects in a straight line. You use it with a rail for smooth, accurate movement. Ball bearings inside reduce friction. You find linear slide blocks in CNC machines, robots, and lab equipment.

A linear slide block bearing uses ball bearings to roll along a rail. This design lowers friction and helps you move loads easily. You get stable, precise motion. You can use these bearings in automation systems for better performance.

You use a linear ball bearing slide block in 3D printers, CNC machines, and factory automation. It works well for jobs that need high accuracy and smooth movement. You can also use it in laboratory devices and pick-and-place robots.

A linear motion ball bearing slide block gives you higher precision and load capacity. You get smoother movement and less noise. Linear rods work for lighter jobs. You should choose slide blocks for heavy-duty automation tasks.

You clean the linear bearing slide block often. You add oil or grease to keep it moving smoothly. You check for damage and replace worn parts. Good seals help keep dust out. Regular care helps your slide block last longer.